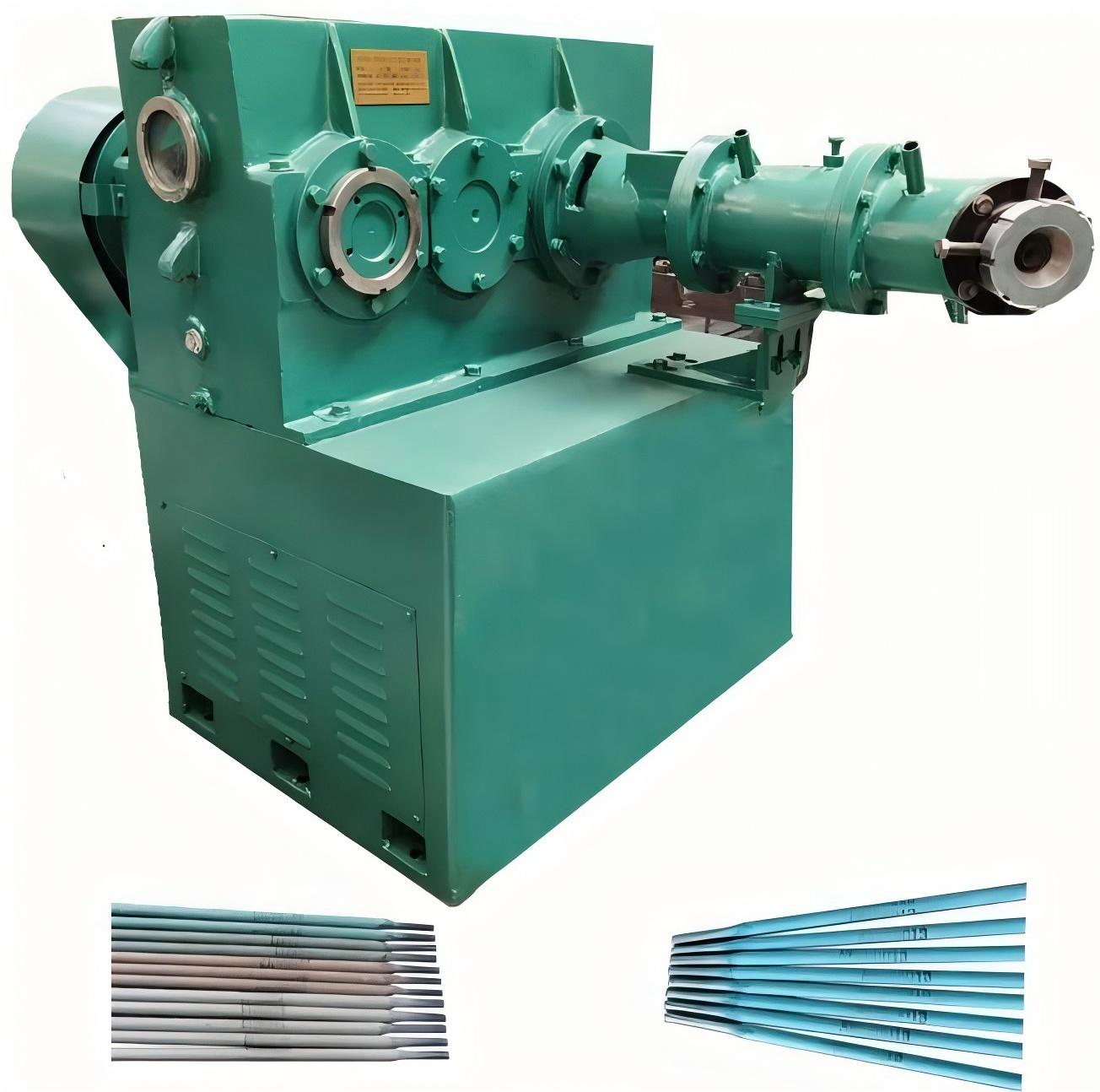

Welding Rod Making Machine

Hydraulic Type Coated Welding Rod Making Machine,Hydraulic Welding Electrode Production Line

- Product description: Hydraulic Type Coated Welding Rod Making Machine,Hydraulic Welding Electrode Production Line

(1) According to the different properties of the electrode coating, the electrode can be divided into two categories: acid electrode and alkaline electrode. Electrodes with a large amount of acid oxides (TiO2, SiO2, etc.) in the coating are called acid electrodes. The coating contains a lot of alkaline oxides (CaO, Na2O, etc.) called alkaline electrodes. The acid electrode can be used for both AC and DC, the welding process performance is good, but the mechanical properties of the weld, especially the impact toughness is poor, suitable for the welding of general low-carbon steel and low-strength low-alloy structural steel. The widest electrode. Alkaline electrode has strong desulfurization and dephosphorization ability, and the coating has a dehydrogenation effect. Welded joints have very low hydrogen content, so they are also called low-hydrogen electrodes. The welding seam of the basic electrode has good crack resistance and mechanical properties, but the process performance is poor.--Generally, DC power supply is used for welding, mainly used for the welding of important structures (such as boilers, pressure vessels and alloy structural steels, etc.) .

(2) According to the different purposes of the electrode, the electrode can be divided into structural steel electrode (carbon steel electrode and low alloy electrode), stainless steel electrode, cast iron electrode, heat-resistant steel electrode, low temperature electrode, surfacing electrode, copper and copper Alloys, nickel and nickel alloys, aluminum and aluminum alloy electrodes, among which structural steel electrodes are the most widely used.

Contact Us

Contact: Ludy

Phone: +86 18638287933

Tel: +86 18638287933

Add: No. 95 Mingli Industrial Park, Huaiyin District, Jinan City , China