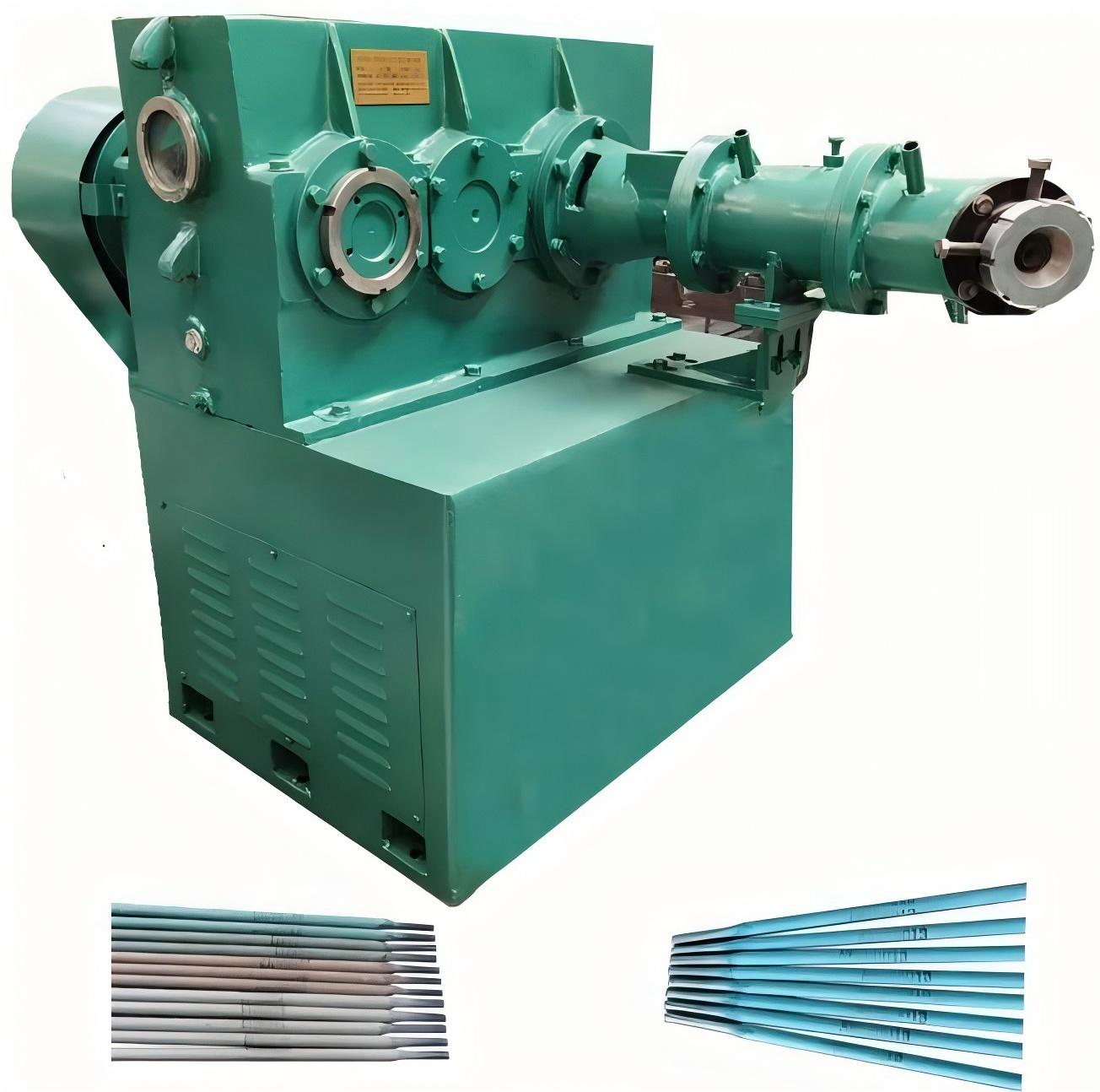

Welding Rod Making Machine

Silver Welding Rod Making Machine,Silver Welding Electrode Production Line

- Product description: Silver Welding Rod Making Machine,Silver Welding Electrode Production Line

Electrode Welding Machinery has good mechanical protection. The gas released by the melting of the coating and the slag formed are used to isolate the air and prevent the intrusion of harmful gases into the molten metal. In addition, it removes harmful impurities and adds beneficial alloying elements for welding. Our equipment enables the weld to meet the required chemical composition and mechanical requirements. There is also the fact that it improves the performance of the welding process by making the arc burning stable and reducing the spatter less.

Electrode dry model

(1) Dry the electrode or dry at low temperature

The process of natural drying of the wet electrode at room temperature is called drying. When drying, the room temperature is generally not less than 15C, and the relative humidity is preferably 50%~55%. The drying time is 8~18h for the electrode produced by the spiral powder coater; it can be determined according to the specific conditions and the variety and specifications of the electrode. grasp. In the drying site, proper ventilation conditions should be improved. Although natural drying can save energy, it requires a long time, a large area, a lot of repetitive labor, and poor working conditions, so it is not suitable for mass production. Low-temperature drying is to place the wet electrode in a drying room or oven with heating and moisture removal devices for drying, which is also called artificial forced drying. The drying temperature is generally 40~60C, and the time is 4~8h, which shortens the time, reduces the floor space, consumes less energy, and improves the quality. It is often used by electrode factories. The purpose of air-drying or low-temperature drying is to remove part of the moisture in the wet electrode and prepare for high-temperature flood baking. Prevent welding: sticking and blistering of the bars, and improve the drying quality of welding. In actual production, the coating of nail welding rod is commonly used, and after the low-temperature drying is qualified without nail indentation, it can be transferred to high-temperature baking.

(2) High temperature baking of welding rod

In the high-temperature drying oven, the air-dried (or low-temperature drying) electrode is dried at a higher temperature to keep its moisture out. This process of drying the medicine skin is called high-temperature baking. When baking at high temperature, it usually goes through the process of low temperature, medium temperature, high temperature and heat preservation-fixed time, cooling and baking (generally below 100C). Due to the different types and specifications of welding rods, there are also great differences in the maximum control temperature and holding time of the high-temperature baking process. The general requirements for the moisture content in the coating of the electrode after high temperature baking are: acid electrode ≤ 1% (except for cellulose type welding regulations); alkaline electrode ≤ 0.4%.

Contact Us

Contact: Ludy

Phone: +86 18638287933

Tel: +86 18638287933

Add: No. 95 Mingli Industrial Park, Huaiyin District, Jinan City , China