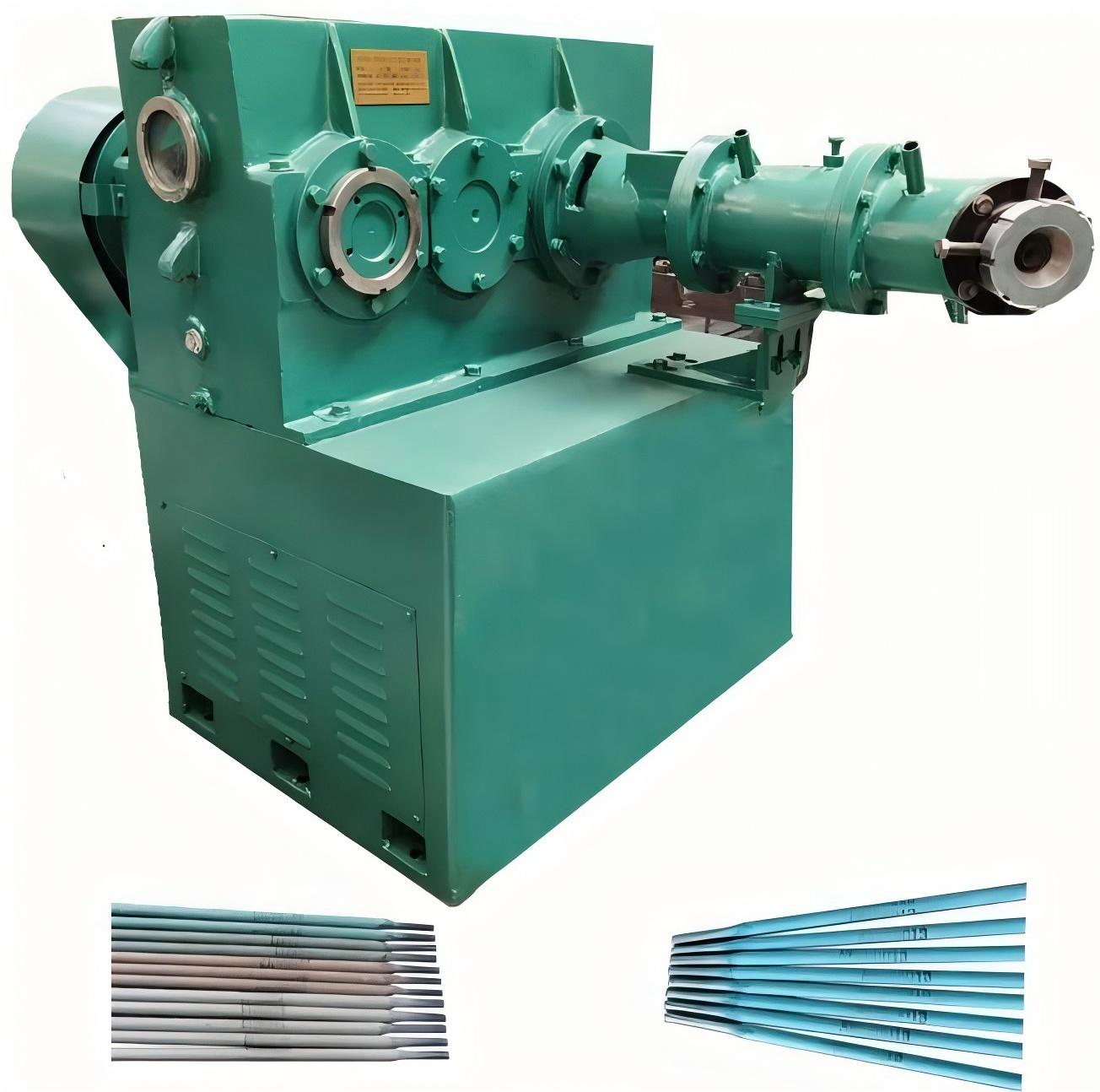

Welding Rod Making Machine

Copper Welding Rod Making Machine,Air-conditioning Welding Electrode Production Line

- Product description: Copper Welding Rod Making Machine,Air-conditioning Welding Electrode Production Line

Electrode Welding Machinery has good mechanical protection. The gas released by the melting of the coating and the slag formed are used to isolate the air and prevent the intrusion of harmful gases into the molten metal. In addition, it removes harmful impurities and adds beneficial alloying elements for welding. Our equipment enables the weld to meet the required chemical composition and mechanical requirements. There is also the fact that it improves the performance of the welding process by making the arc burning stable and reducing the spatter less.

Maintenance of core wire line for welding rod

1 Daily maintenance

1.1 Check whether the equipment grounding wire is reliable.

1.2 Check whether the electrical control, temperature adjustment instrument and component wiring are loose or fall off.

1.3 Check whether the temperature sensing element is damaged.

1.4 Strictly start, run and stop in accordance with the operating regulations, keep a record of the operation, and keep the appearance of the equipment clean and tidy.

2 Level 1 maintenance content

2.1 Check and clean the furnace door, drawers, and slips for bumps or damage, and repair them. Clean the furnace and drawers and check the exhaust valve.

2.2 Check all parts of the equipment and tighten the bolts.

2.3 Purge electrical components and dust inside and outside the instrument box, check the loose connection points of each line.

2.4 Check temperature control, automatic control instruments and component joints.

3 Secondary maintenance content

3.1 Complete all the contents stipulated in the equipment level 1 maintenance.

3.2 Check whether the control system circuit is aging, whether the contact is overheated, replace the aging circuit, and deal with the overheated contact.

3.3 Check whether the contacts of electrical components such as relays and contactors are tight, sensitive, and whether there is any jamming. The contact surface should not be less than 2/3 of the contact surface.

3.4 Check the temperature regulator and time relay, and make adjustments.

4 Periodic inspection of drying box for core wire line for welding rod

4.1 Thermocouples and temperature adjustment indicators used for temperature detection should be inspected regularly, at least once a year.

4.2 Various control instruments of the control system shall be inspected once a year according to the requirements of instrument performance parameters to check their accuracy and sensitivity.

Contact Us

Contact: Ludy

Phone: +86 18638287933

Tel: +86 18638287933

Add: No. 95 Mingli Industrial Park, Huaiyin District, Jinan City , China